The Project:

Third Party Testing of DPI’s Injection Molded UHMW Parts

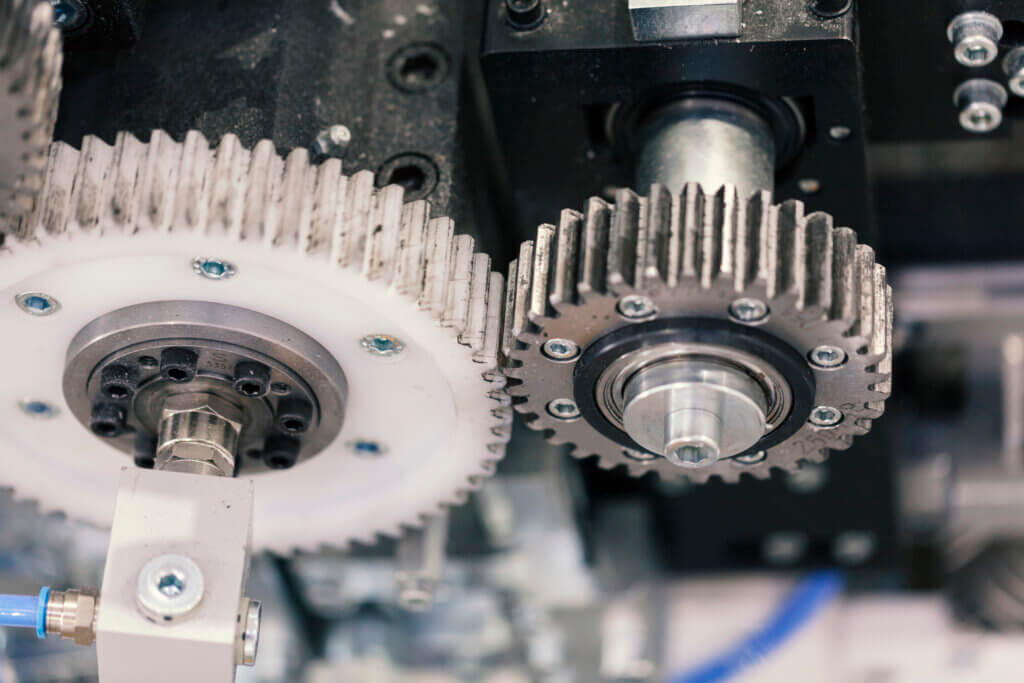

In further testing of one of our proprietary Injection Molded UHMW formulations against standard extruded UHMW sheet stock, we continue to see incredible durability results. Through third-party lab testing, an extensive study was conducted to ensure that DPI’s injection molded UHMW parts and components would perform as well as those produced from standard sheet-stock UHMW, which is commonly used in high-wear part applications. The specific parts used in this testing were from our line of Injection Molded UHMW drag paddles, which are designed for use in grain handling systems, in this case.

The Challenge:

High Wear Parts: Injection Molded UHMW vs. Extruded Sheet

High-wear parts are essential to many applications and industries. Because of this, material scientists and engineers are always searching for better-wearing materials and analyzing for performance and wear life. High-wear parts regularly have to be replaced, so minimizing their cost is very important to our customers. With this in mind, an outside lab tested both our injection molded UHMW parts and extruded sheet stock UHMW parts for: abrasion resistance, tensile properties, deflection under load, deflection with a cyclical load, and hardness.

The Results:

Uncompromised Performance and Cost Savings is Achieved

Third-party testing and the resulting data proved that DPI’s Injection Molded UHMW parts outwear parts made from standard extruded UHMW sheet stock. In fact, in this drag paddle testing, our Taber abrasion wear index was less than half of that of standard extruded sheet at 72.8 versus 164.

Learn More:

Discover the Possibilities with Plastic from DPI

If you have UHMW parts that need to deliver longer wear life and help you reduce part costing, these test results confirm that it’s time to give us a call.